Diffusion bonding / Thermo-compression bonding

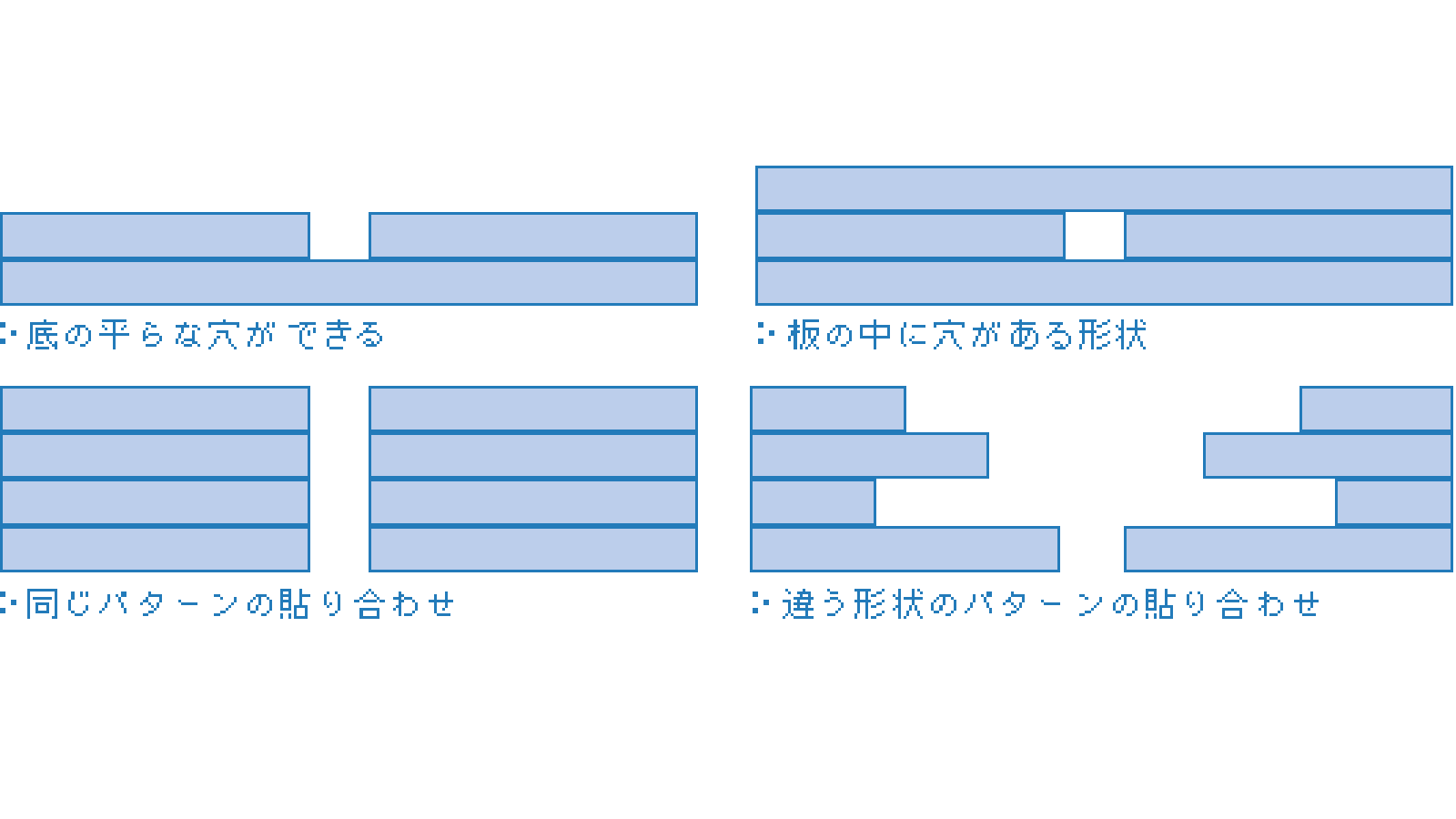

Although the etching process itself can be used with thin plates only, thicker products can also be manufactured by stacking and joining processed thin plates using diffusion bonding or thermo-compression bonding methods (base angle of 90 degrees (right angle) is also available) . Metals are usually joined together by adhesive or spot welding, but these methods have a number of drawbacks. Such bonds peel off at high temperatures, are difficult to clean, and spot welding creates gaps. To solve these problems, we recommend our proprietary thermo-compression bonding method.

Advantages of diffusion bonding

High strength and small dimensional changes due to lamination of thin plates

Clean and problem-free finish with gas generation and cleaning of protruding parts

Mass-production allows cost savings

Deep holes, tapered holes and other complex shapes and channel structures are possible.

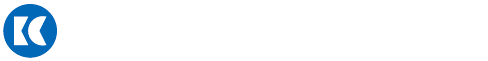

Manufacturing process image

Joint cross-section

Joinable materials

Stainless steel + stainless steel

Examples: SUS304+SUS304 SUS430+SUS430

42 alloy + 42 alloy

Invar + invar

Titan + titan

Copper + copper

We also can handle other materials, so please consult as.

Number of joined plates and thickness

Possible sizes vary depending on the plate thickness and shape, so please contact us for more information.

Joining application examples

Fuel cell separators

Deposition masks

Suction plates

Carrier tape

Semiconductor manufacturing jigs

Electronics components

Various filters

Heat exchanger parts

Fuel cell parts

Wire bonders

Heat sinks, etc.

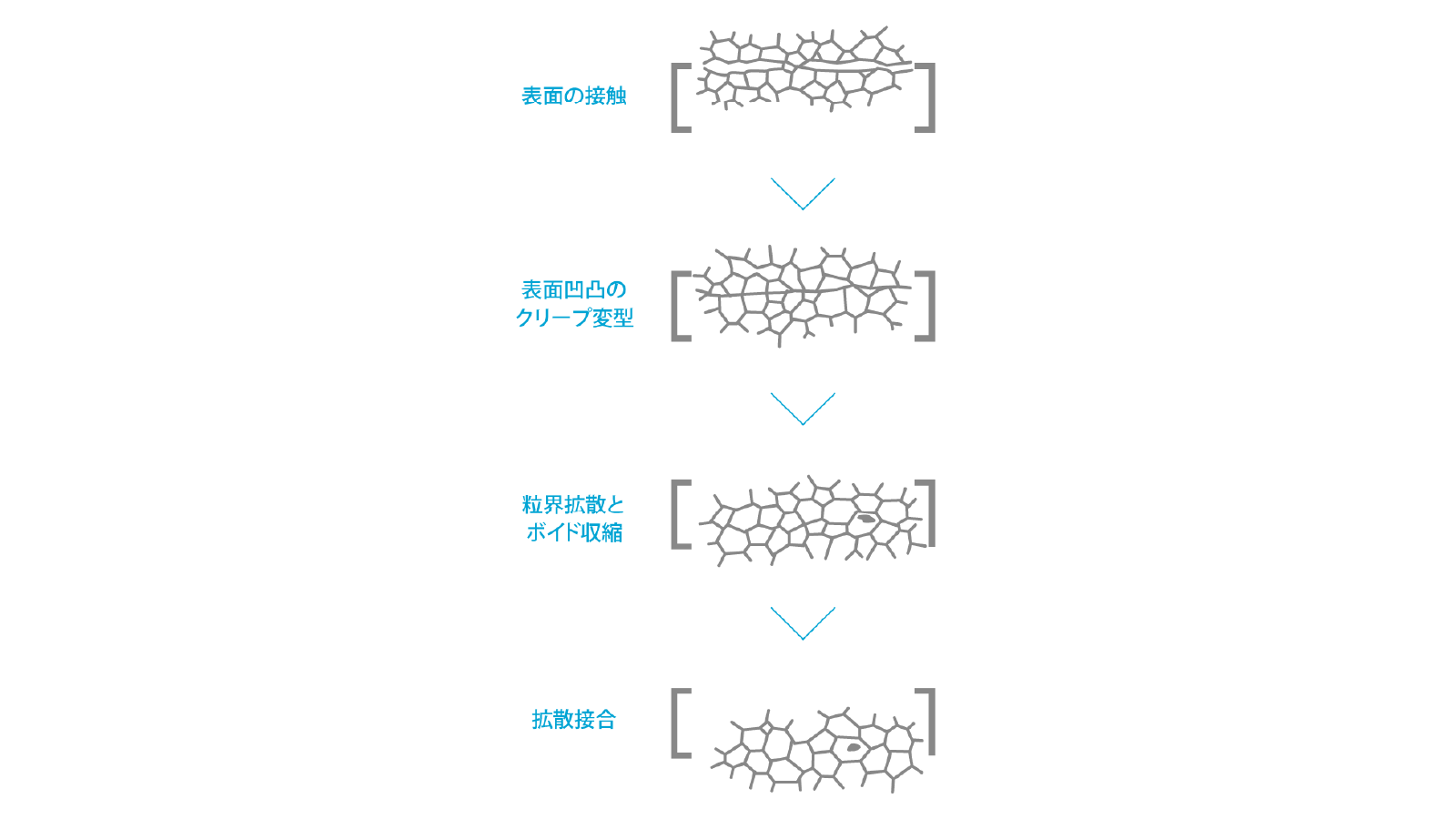

Principle of diffusion bonding

A metal bond is formed when two metal surfaces are brought close to each other at an atomic level. Therefore, joining is theoretically possible by bringing two metals close together.

Diffusion bonding is a process based on this principle. In it two metal surfaces are metallurgically bound in a solid state using heat and pressure.