Photo-etching technology

Photo-etching is a chemical precision processing technology that uses a photomechanical process to form a corrosion-resistant film in the required pattern on metals, which are then subjected to partial corrosion. Since processed shapes are determined by precision photographic images, the technology allows complex, microscopic patterns on the scale of micrometers.

Advantages of photo-etching

The process can be performed in a short time, usually within a week, regardless of the shape or size of the processed area.

Ideal for mass production because many parts can be processed simultaneously

High precision process without burrs, deformations and work hardening

Significant reduction of initial costs because no need for expensive molds used in press working.

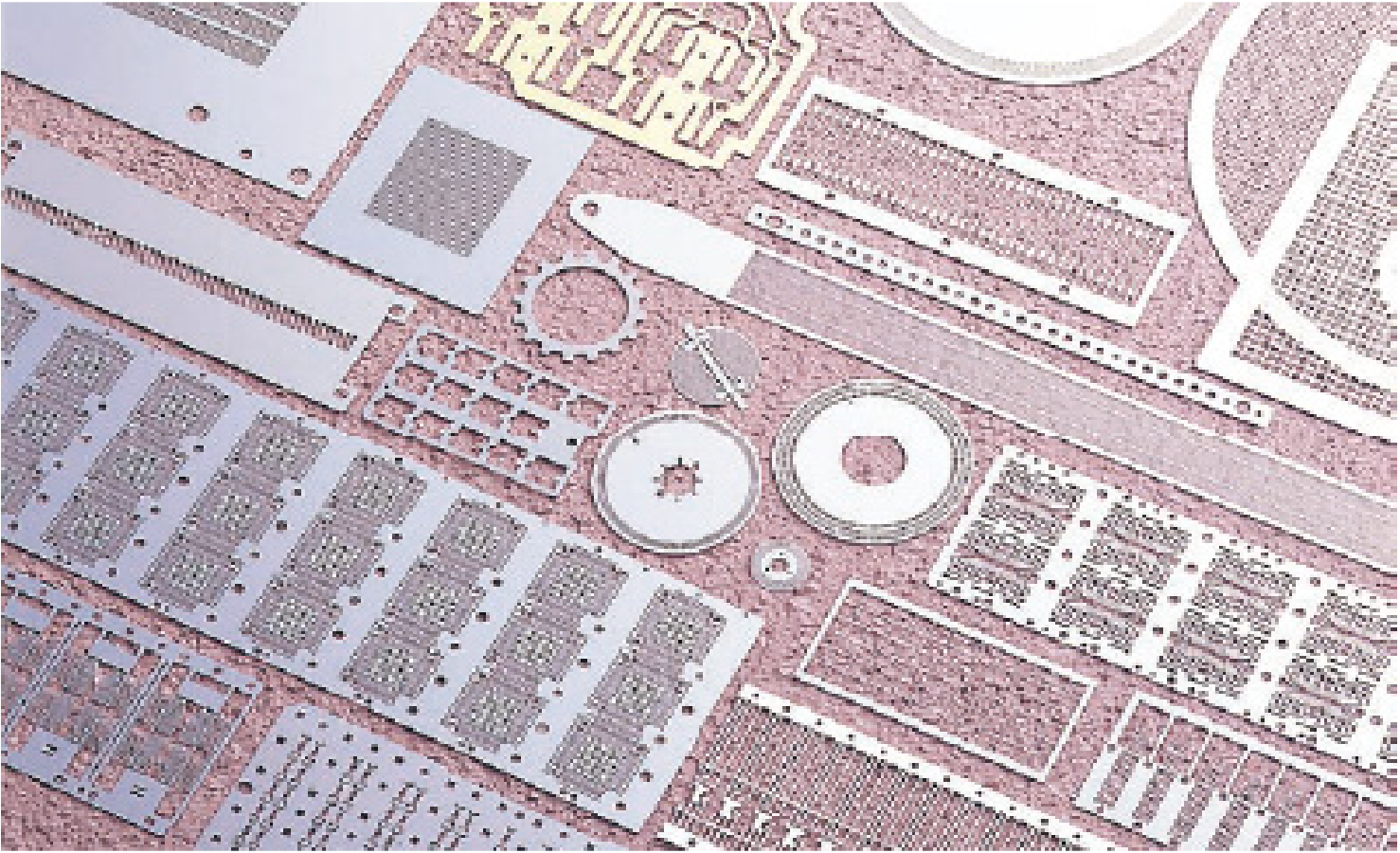

Work processes

Process accuracy and limits -1.Plate thickness

Plate thickness from 0.005t to 2.0t. Please consult us about plates with other thickness.

Process accuracy and limits -2.Materials that can be processed

Stainless steel, copper and copper alloys, aluminum, phosphor Bronze, brass, beryllium copper, nickel, permalloy, titanium, etc.

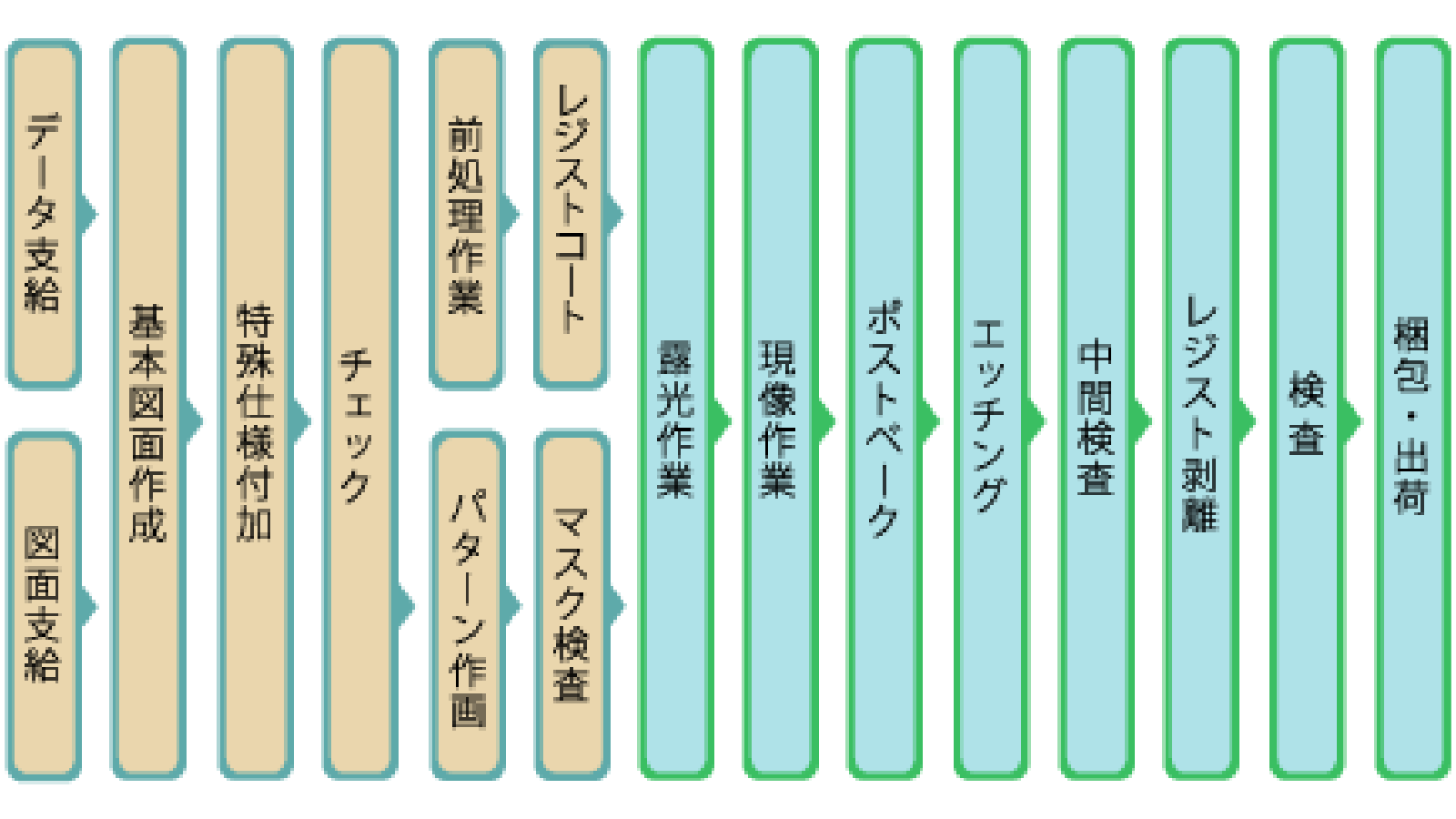

Process accuracy and limits -3.Corner shape

When etching corner shapes, outer and inner corners have radius R.

The radius of outer corners is 40% of the plate thickness.

The radius of inner corners is 80% of the plate thickness.

Process accuracy and limits -4.Dimensional tolerances

Dimensional tolerances vary with plate thickness, so it is difficult to determine a definitive standard and there is always a certain degree of variance. Generally, the standard tolerance is ±10% to 15% of the plate thickness. However, we can meet even stricter requirements for prototypes and small lots, so please consult us in advance.

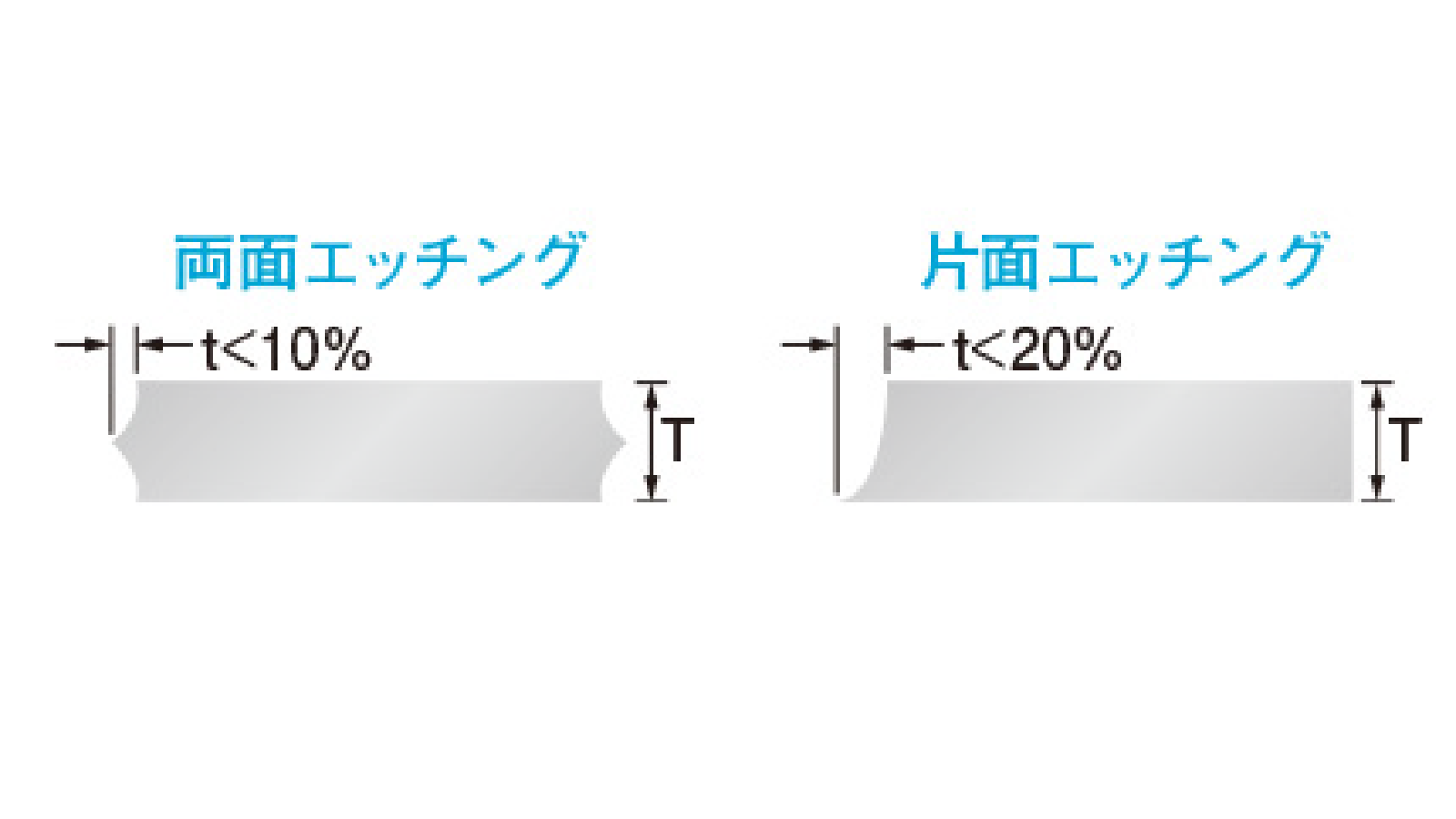

Process accuracy and limits -5.Cross-section shape

Since the phenomenon called side-etching cannot be avoided completely, the cross-section of the product will be as shown in the figure. For double-sided etching the side-etching does not exceed 10% of the plate thickness. For single-sided etching the effect of the side-etching does not exceed 20% of the plate thickness.

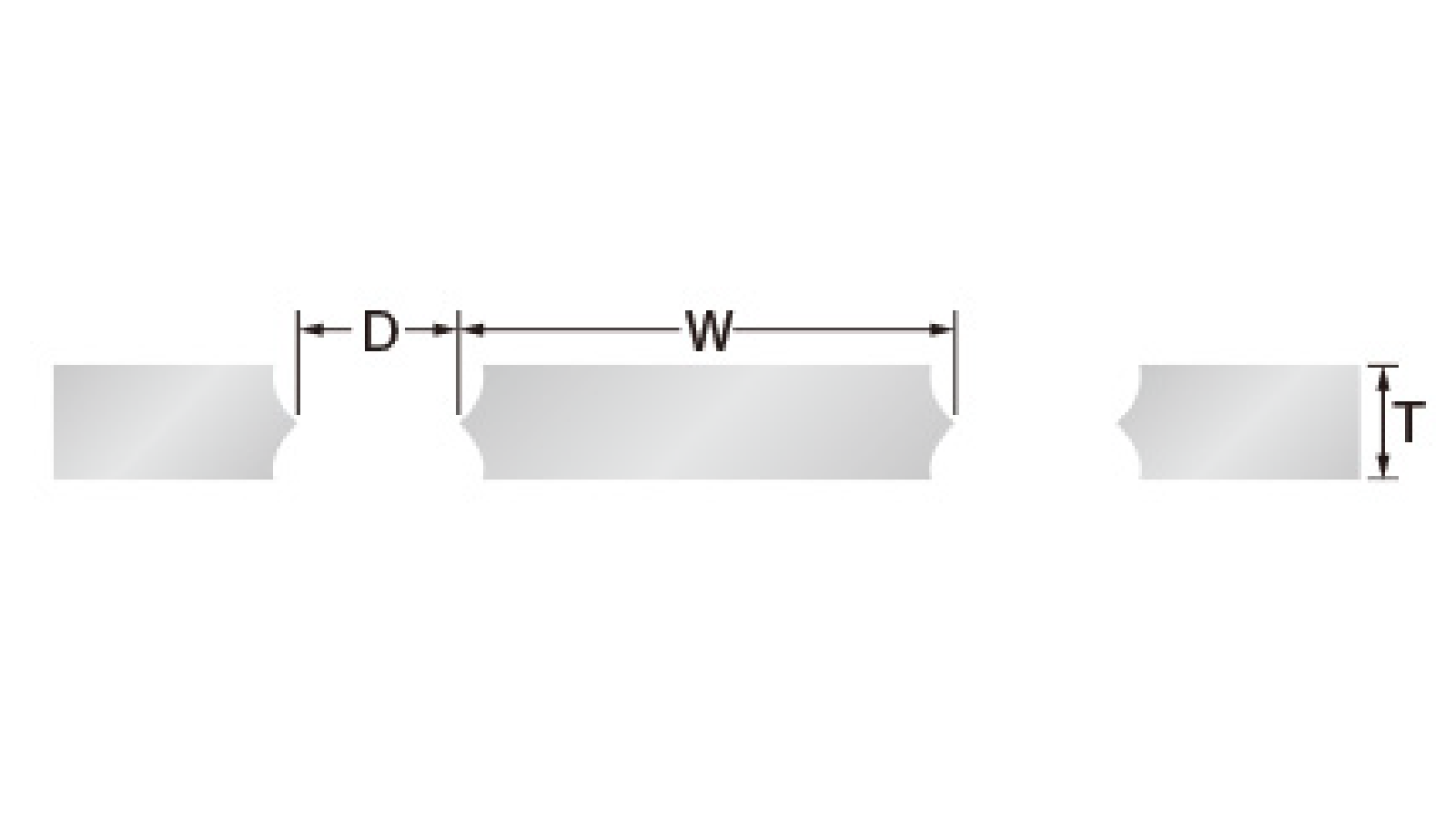

Process accuracy and limits -6.Processing limits

The minimum dimension D is equal to the plate thickness. MIN/0.05mm.

The minimum dimension W is equal to 1/2 of the plate thickness. MIN/0.03mm.

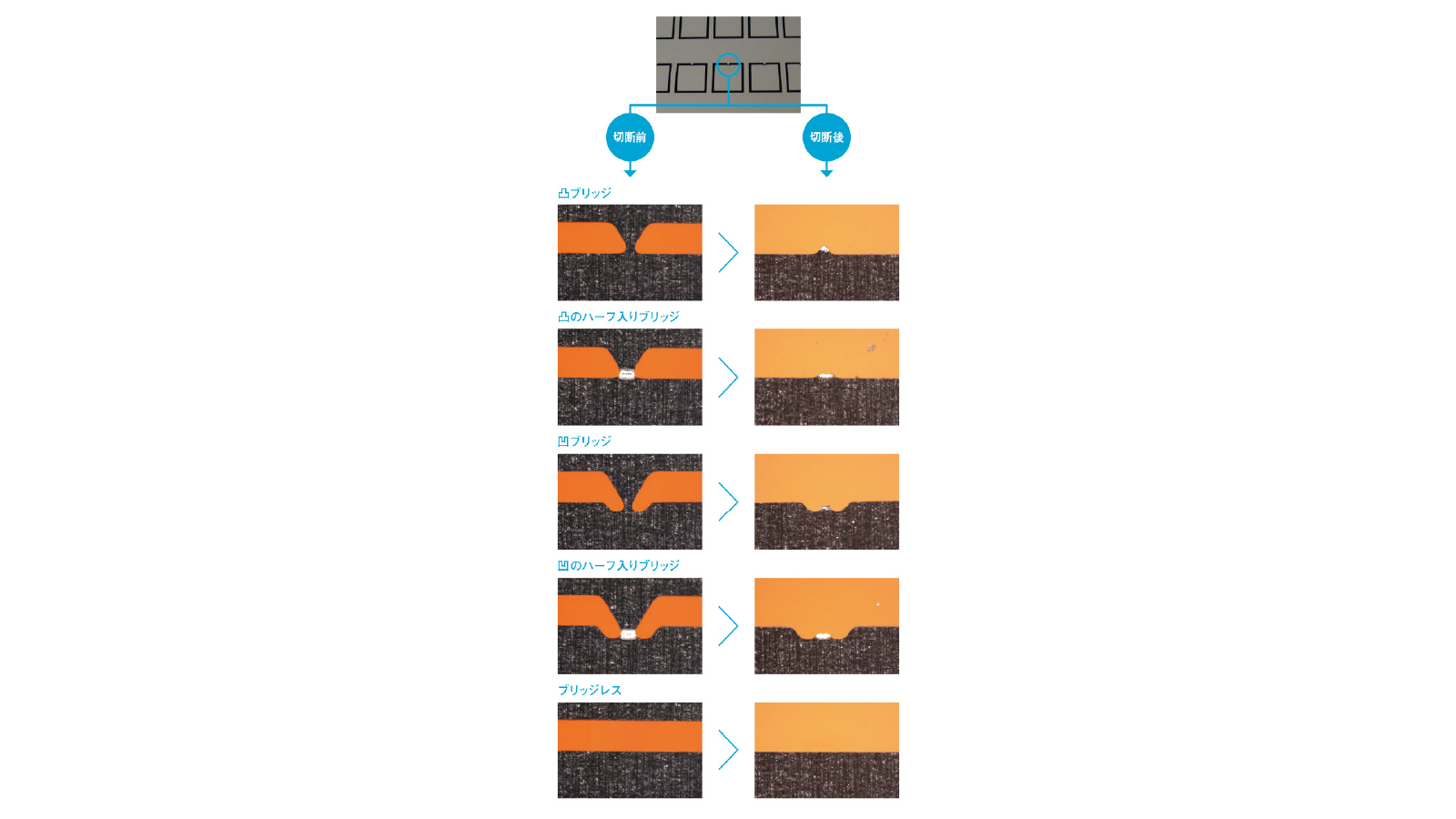

Process accuracy and limits -7.Bridge shapes

Bridges (connections) are necessary parts of the etching process. Bridges must be placed where they will not interfere with the application or post-processing of the product.

Please specify the position and shape of the bridges in advance.

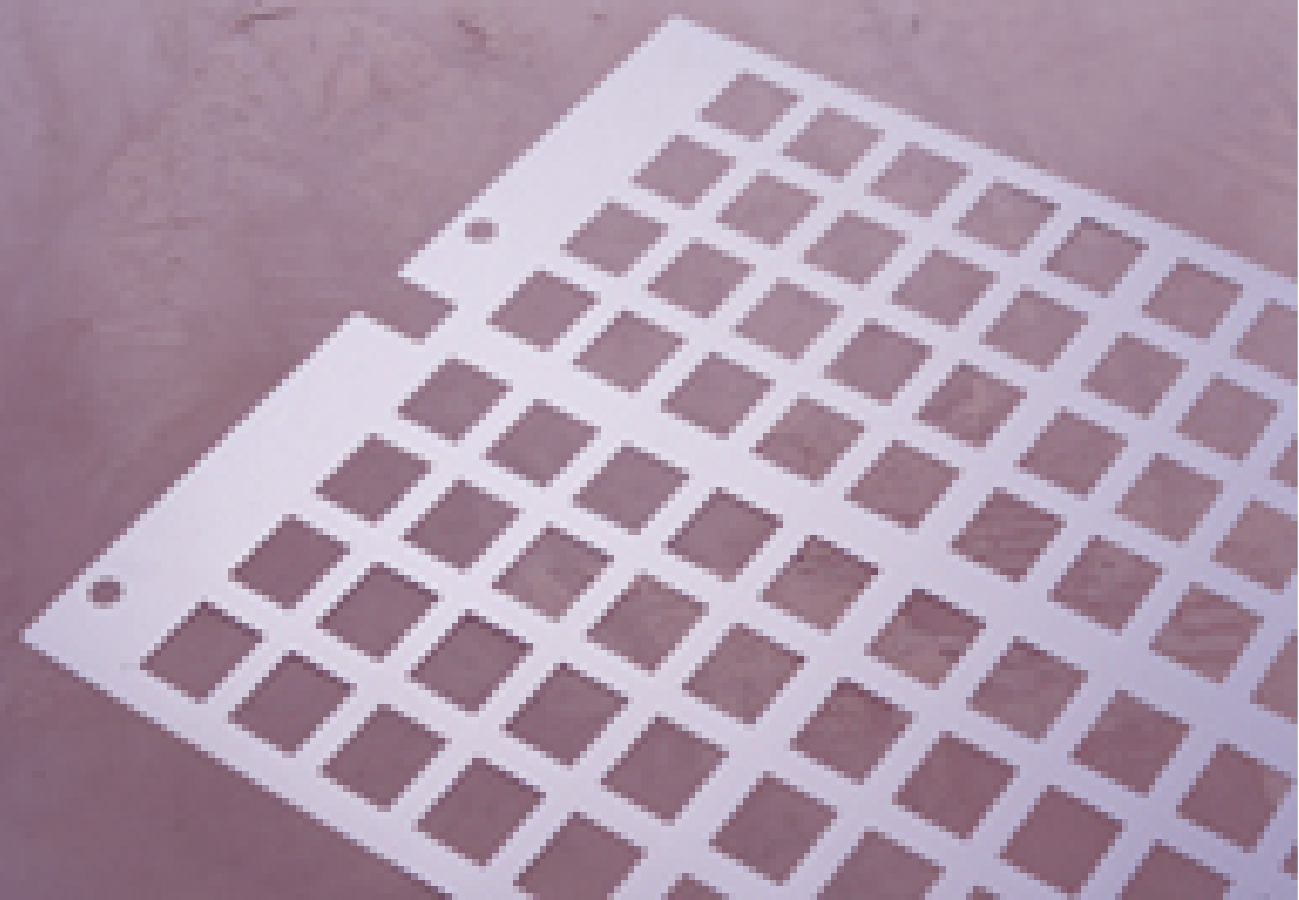

Large-scale etching

Etching of large-sized products such as metal masks for large glass substrates for LCD TVs, shim plates for large machine tools, etc. is possible. We have a lot of experience in manufacturing semiconductor components such as various types of deposition masks and mesh patterns. We can handle everything from small quantities of prototypes to mass production.

Maximum processing size: 500×2000mm

Special metal etching

We can also process special materials such as aluminum, molybdenum, titanium, Inconel, etc.

Please feel free to contact us when you need etching services for special metals. We can handle even small quantities of prototypes.

Half-etching and stepped engraving

Normally, the same pattern shape is etched on both sides of the plate when making through-holes. However, by controlling the etching balance on each side, it is possible to etch any shape or to etch only one side of the material to the middle of the plate. The processing depth is usually about 60% of the plate thickness. We also offer stepped engraving. (Up to 5 engraving steps)

Our special feature is clean and detailed half-face finish using a special etching solution, especially for stainless steel materials.