Electroforming

A process that uses electrodeposition technology to form thin metal plates into a desired shape with high precision. It allows to manufacture three-dimensional components such as fine meshes and encoders.

Electroforming

Electroforming is a process that uses electrodeposition technology to form thin metal plates into a desired shape with high precision. It allows to manufacture three-dimensional components such as fine meshes and encoders.

Process limits and accuracy -1.Plate thickness

From 0.005t Please consult about other thickness values

Process limits and accuracy -2.Materials that can be processed

Nickel, copper

Process limits and accuracy -3.Corner shape

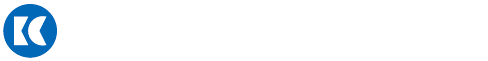

Electroforming produces outer and inner corners with radius R.

The radius of outer corners is 50% of the plate thickness. The radius of inner corners is 20% of the plate thickness.

Process limits and accuracy -4.Dimensional tolerances

Dimensional tolerances vary depending on the thickness of the plate; a minimum tolerance of ±5μ is possible.

We can also meet even more strict requirements, so please contact us for more information.

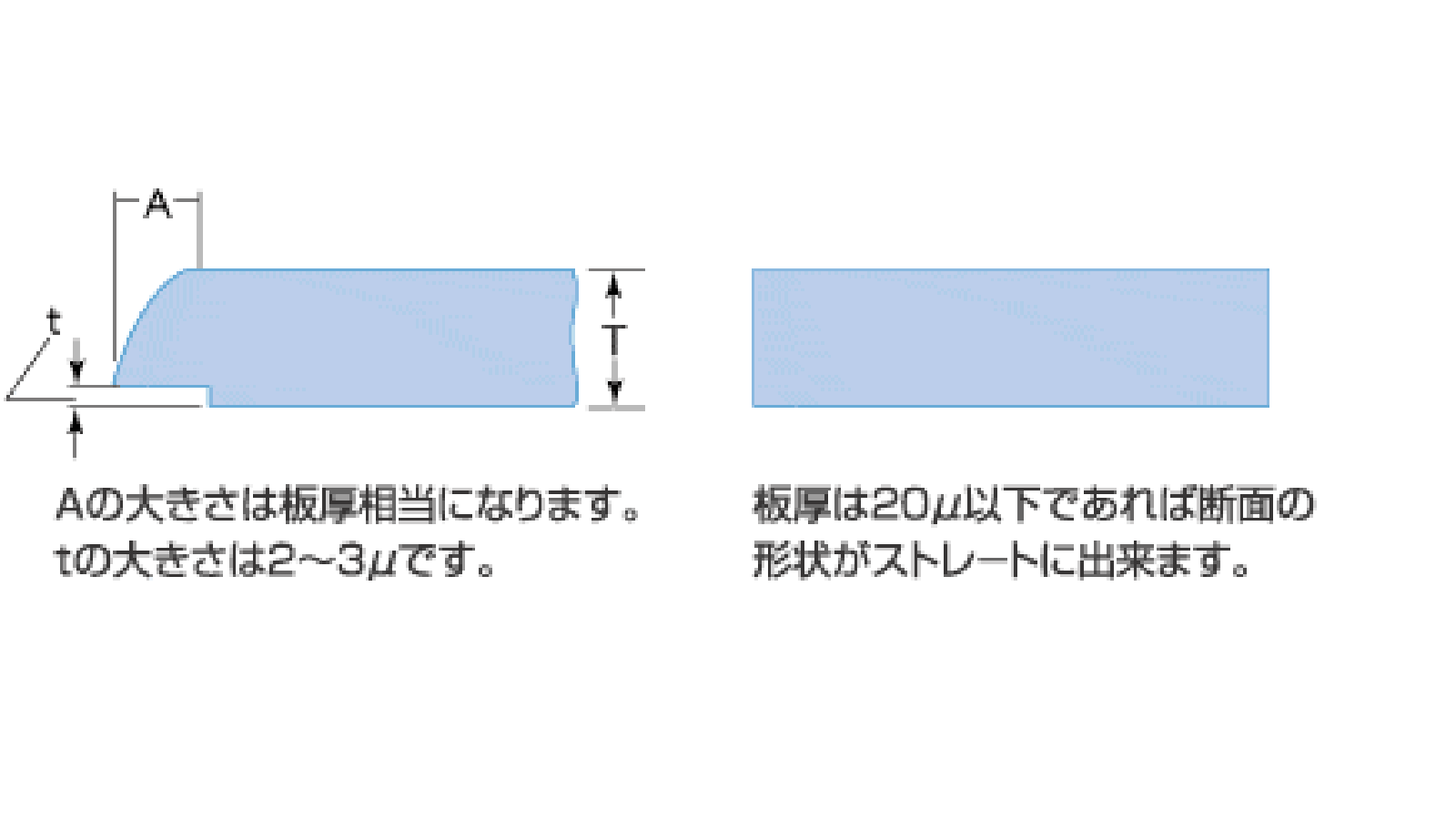

Process limits and accuracy -5.Cross-section shape

Two cross-section shapes are available. The first shape is the overhanging shape shown in the lower left figure. A straight cross-section is also possible if the thickness of the plate is less than 20μ.

Process limits and accuracy -6.Processing limits

The minimum dimension D is 5μ or more. However, it may be difficult to obtain due to the pitch. The minimum dimension W is 30μ or more.

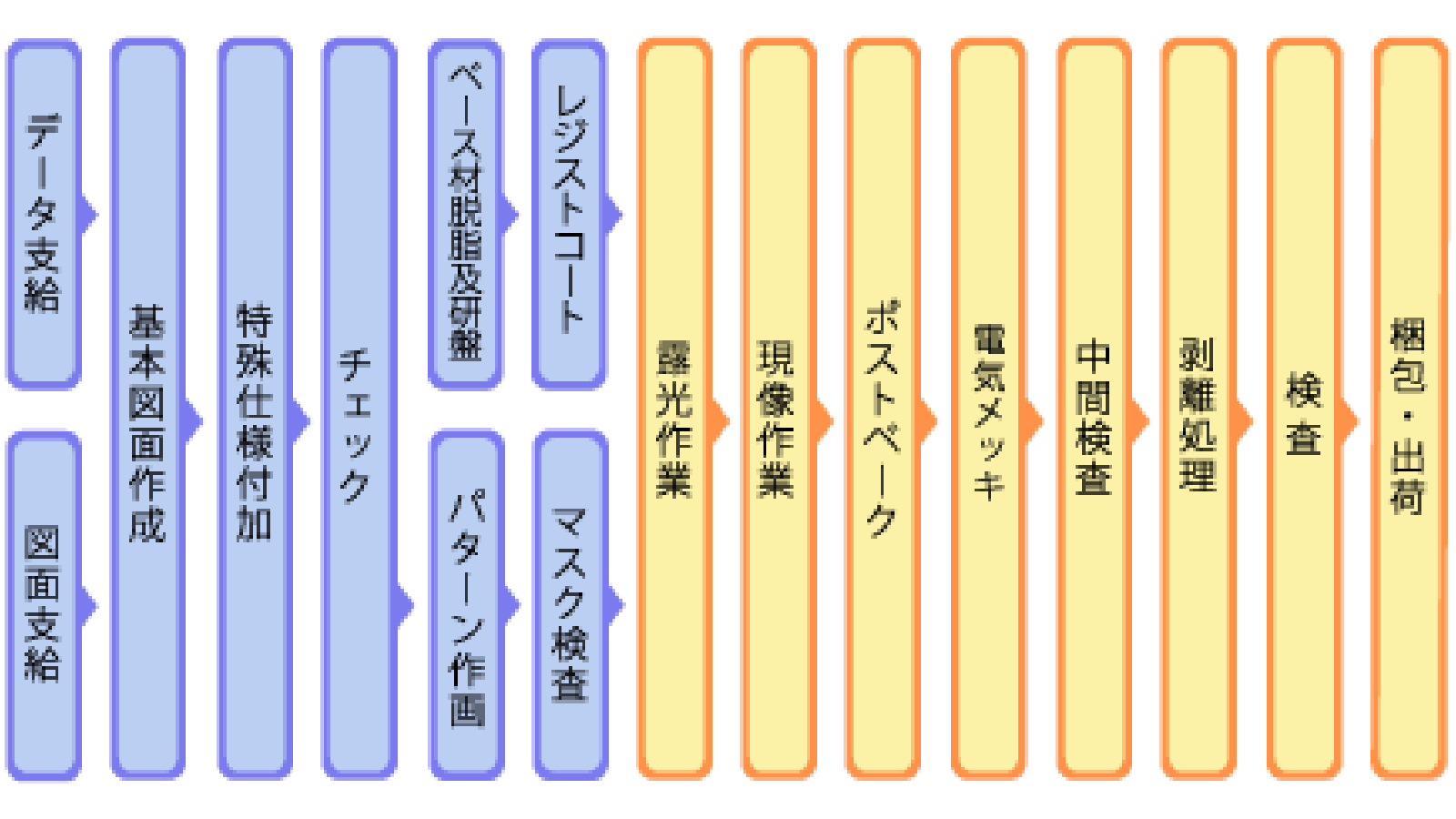

Work processes